Stress Cracks

Stress cracks are internal fissures in the horneous (hard) endosperm of a corn kernel. The pericarp (or outer covering) of a stress-cracked kernel is typically not damaged, so the kernel may appear unaffected at first glance, even if stress cracks are present.

Stress crack measurements include ‘stress cracks’ (the percentage of kernels with at least one crack) and stress crack index, which is the weighted average of single, double and multiple stress cracks. Both measurements use the same sample of 100 intact kernels with no external damage. ‘Stress cracks’ measures only the number of kernels with stress cracks; whereas, the stress crack index shows the severity of stress cracking. For example, if half of the kernels have only a single stress crack, ‘stress cracks’ is 50%, and the stress crack index is 50 (50 x 1). However, if half of the kernels have multiple stress cracks (more than two cracks), indicating a higher potential for handling breakage, ‘stress cracks’ remains at 50%, but the stress crack index becomes 250 (50 x 5). Lower values for ‘stress cracks’ and the stress crack index are always preferable. Over the past eight years, both stress cracks and stress crack index were performed. However, there was a very high correlation between the two factors (r = 0.99). Therefore, only the stress crack measurements were performed and reported beginning with the 2019/2020 Harvest Report.

The cause of stress cracks is pressure buildup due to moisture and temperature gradients within the kernel’s horneous endosperm. This can equate to the internal cracks that appear when dropping an ice cube into a lukewarm beverage. The internal stresses do not build up as much in the soft, floury endosperm as in the hard, horneous endosperm; therefore, corn with a higher percentage of horneous endosperm is more susceptible to stress cracking than softer grain. A kernel may vary in severity of stress cracking and can have one, two or multiple stress cracks. The most common cause of stress cracks is high-temperature drying that rapidly removes moisture. The impact of high levels of stress cracks on various uses includes:

- General: Increased susceptibility to breakage during handling. This may lead to processors needing to remove more broken corn during cleaning operations and a possible reduction in grade or value.

- Wet Milling: Lower starch yields due to the increased difficulty in separating starch and protein. Stress cracks may also alter steeping requirements.

- Dry Milling: The lower yield of large flaking grits (the prime product of many dry milling operations).

- Alkaline Cooking: A method of non-uniform water absorption leading to overcooking or undercooking, which affects the process balance.Growing conditions will affect crop maturity, timeliness of harvest and the need for artificial drying, which will influence the degree of stress cracking found from region to region. For example, late maturity or late harvest caused by weather-related factors, such as rain-delayed planting or cool temperatures, may increase the need for artificial drying, thus potentially increasing the occurrence of stress cracks.

Results: Stress Cracks

U.S. Aggregate stress cracks in 2019 averaged 9%, which was higher than in 2018, 2017 and the 5YA (all 5%).

U.S. Aggregate stress cracks in 2019 averaged 9%, which was higher than in 2018, 2017 and the 5YA (all 5%).- U.S. Aggregate stress cracks standard deviation in 2019 (7%) was similar to 2018 (6%), 2017 (8%) and the 5YA (7%).

- Stress cracks in 2019 ranged from 0 to 95%, compared to 0 to 88% in 2018 and 0 to 90% in 2017.

- The percentage of samples with less than 10.0% stress cracks in 2019 (74.0%) was lower than in 2018 (89.0%) and 2017 (86.8%). Also, in 2019, 10.8% of the samples had stress cracks above 20.0%, which is higher than in 2018 (6.3%) and 2017 (7.7%). Stress crack distributions indicate that 2019 corn should be higher in breakage susceptibility than 2018 and 2017.

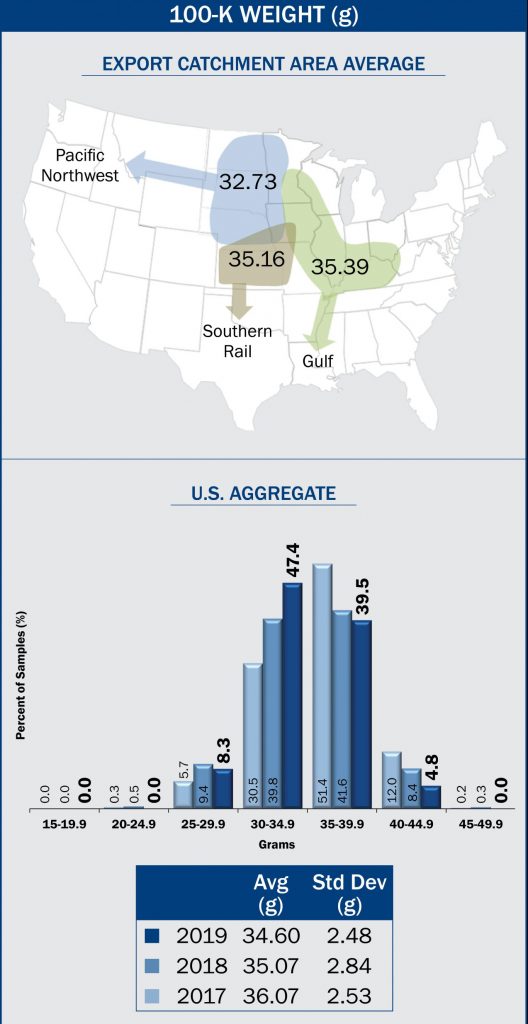

- Stress crack averages in 2019 for Gulf, Pacific Northwest and Southern Rail ECAs were 10, 9 and 6%, respectively. Among all ECAs, the Southern Rail had the lowest stress cracks in 2019, 2018, 2017 and the 5YA.

- Much of the 2019 crop was planted up to a month later than normal, resulting in a later harvest with slow late-season dry-down conditions. This led to higher moistures at harvest and increased need for artificial drying, resulting in the potential for higher stress cracks than in previous years. Average moistures (17.5%) were above those of 2018, 2017 and the 5YA.