Grade Factors

The 2019/2020 Harvest Report samples (each about 2,200 grams) were sent directly from the local grain elevators to the Illinois Crop Improvement Association’s Identity Preserved Grain Laboratory (IPG Lab) in Champaign, Illinois. Upon arrival, samples above 16.0% moisture were ambient air-dried, if needed, to a suitable moisture content to prevent any subsequent deterioration during the testing period. Selected samples were dried using an ambient-air drying technique to prevent stress cracking and heat damage. Next, the samples were split into two subsamples of about 1,100 grams each using a Boerner divider, while keeping the attributes of the grain sample distributed evenly between the two subsamples. One subsample was delivered to the Champaign-Danville Grain Inspection (CDGI), in Urbana, Illinois, for grading. CDGI is the official grain inspection service provider for east-central Illinois as designated by the USDA FGIS. The grade testing procedures were in accordance with FGIS’s Grain Inspection Handbook and are described in the following section. The other subsample was analyzed at IPG Lab for the chemical composition and other physical factors, following either industry norms or well-established procedures in practice for many years. IPG Lab has received accreditation under the ISO/IEC 17025:2005 International Standard for many of the tests. The full scope of accreditation is available at http://www.ilcrop.com/labservices.

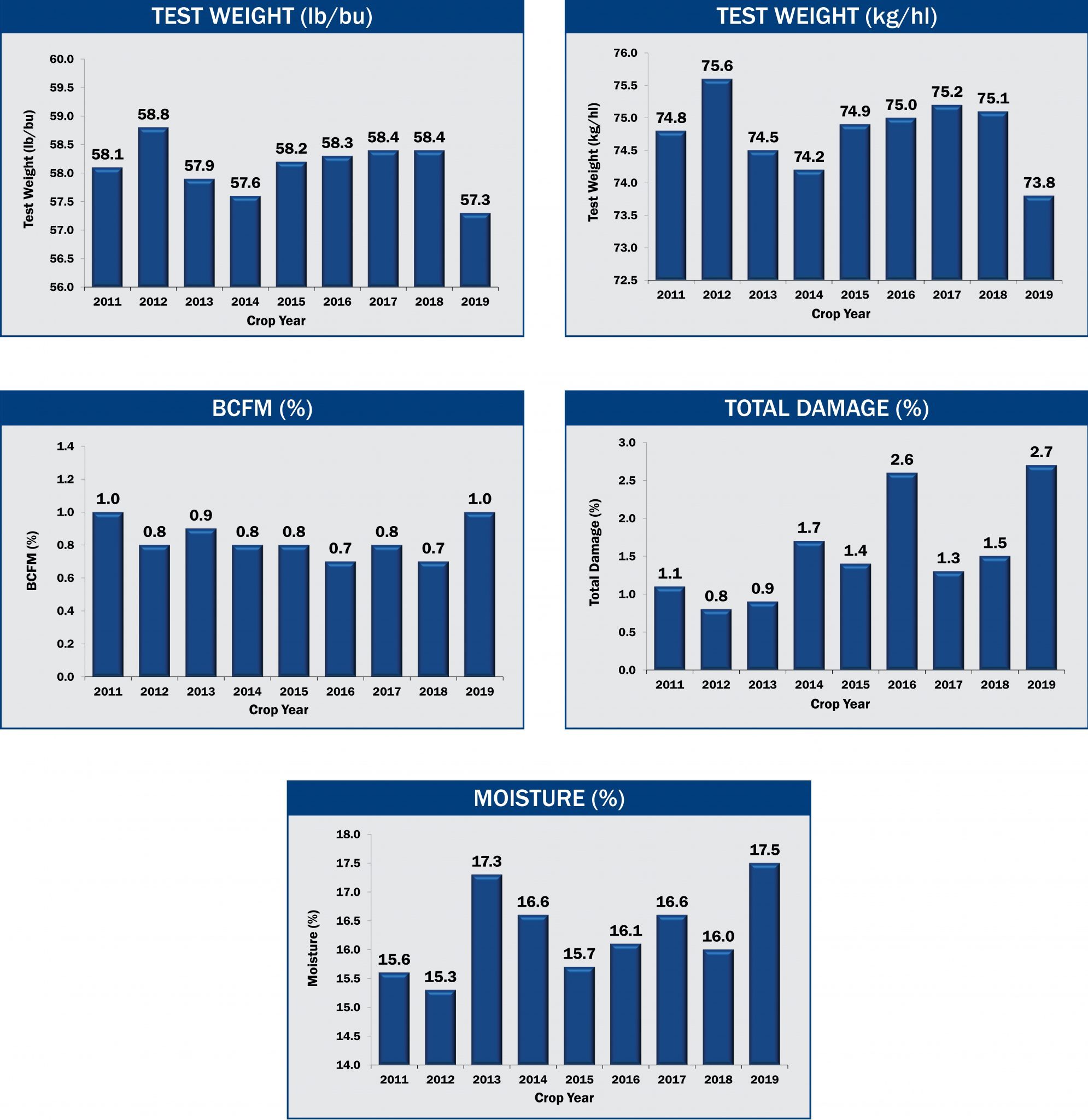

Test Weight

Test weight is a measure of the volume of grain that is required to fill a Winchester bushel (2,150.42 cubic inches). Test weight is a part of the FGIS Official U.S. Standards for Corn grading criteria.

The test involves filling a test cup of known volume through a funnel held at a specific height above the test cup to the point where grain begins to pour over the sides of the test cup. A strike-off stick is used to level the grain in the test cup, and the grain remaining in the cup is weighed. The weight is then converted to and reported in the traditional U.S. unit, pounds per bushel (lb/bu).

Broken Corn and Foreign Material

BCFM is part of the FGIS Official U.S. Standards for Grain and grading criteria.

The BCFM test determines the amount of all matter that passes through a 12/64th-inch round-hole sieve and all matter other than corn that remains on the top of the sieve. BCFM measurement can be separated into broken corn and foreign material. Broken corn is defined as all material passing through a 12/64th-inch round-hole sieve and retained on a 6/64th-inch round-hole sieve. The definition of foreign material is all material passing through the 6/64th-inch round-hole sieve and the coarse non-corn material retained on top of the 12/64th-inch round-hole sieve. BCFM is reported as a percentage of the initial sample by weight.

Total Damage and Heat Damage

Total damage is part of the FGIS Official U.S. Standards for Grain grading criteria.

A trained and licensed inspector visually examines a representative working sample of 250 grams of BCFM-free corn for damaged kernels. Types of damage include blue-eye mold, cob rot, dryer-damaged kernels (different from heat-damaged kernels), germ-damaged kernels, heat-damaged kernels, insect-bored kernels, mold-damaged kernels, mold-like substance, silk-cut kernels, surface mold (blight), mold (pink Epicoccum) and sprout-damaged kernels. Total damage is reported as the weight percentage of the working sample that is total damaged grain.

Heat damage is a subset of total damage and consists of kernels and pieces of corn kernels that are materially discolored and damaged by heat. Heat-damaged kernels are determined by a trained and licensed inspector visually inspecting a 250-gram sample of BCFM-free corn. Heat damage, if found, is reported separately from total damage.

Moisture

The moisture recorded by the elevators’ electronic moisture meters at the time of delivery is reported. Electronic moisture meters sense an electrical property of grains called the dielectric constant that varies with moisture. The dielectric constant rises as moisture content increases. Moisture is reported as a percent of total wet weight.

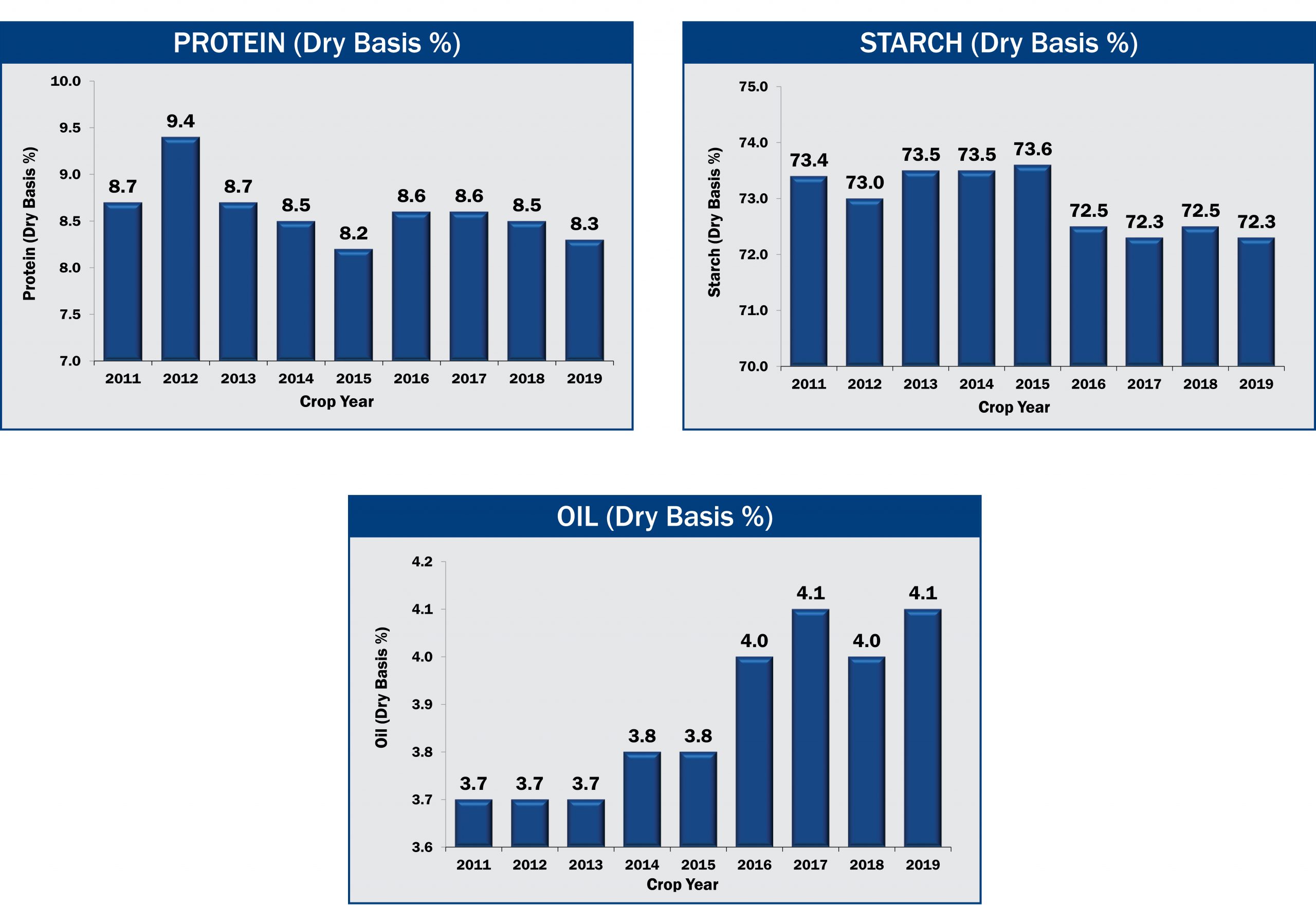

Chemical Composition

Near-Infrared Transmission Spectroscopy (NIR) Proximate Analysis

The chemical composition (protein, oil and starch concentrations) of corn is measured using NIR. The technology uses unique interactions of specific wavelengths of light with each sample. It is calibrated to traditional chemistry methods to predict the concentrations of protein, oil and starch in the sample. This procedure is nondestructive to the corn.

Chemical composition tests for protein, oil and starch were conducted using a 550-gram to

600-gram sample in a whole-kernel Foss Infratec 1241 NIR instrument. The NIR was calibrated to chemical tests, and the standard errors of predictions for protein, oil and starch were about 0.22%, 0.26% and 0.65%, respectively. Comparisons of the Foss Infratec 1229 used in Harvest Reports prior to 2016 to the Foss Infratec 1241 on 21 laboratory check samples showed the instruments averaged within 0.25%, 0.26% and 0.25% points of each other for protein, oil and starch, respectively. Results are reported on a dry basis percentage (percent of non-water material).