100-Kernel Weight

Increasing 100-kernel weight (reported in grams) indicates larger kernel size. Kernel size affects drying rates. As kernel size increases, the volume-to-surface area ratio becomes higher, and as the ratio gets higher, drying becomes slower. In addition, large, uniform-sized kernels often enable higher flaking grit yields in dry milling.

Results

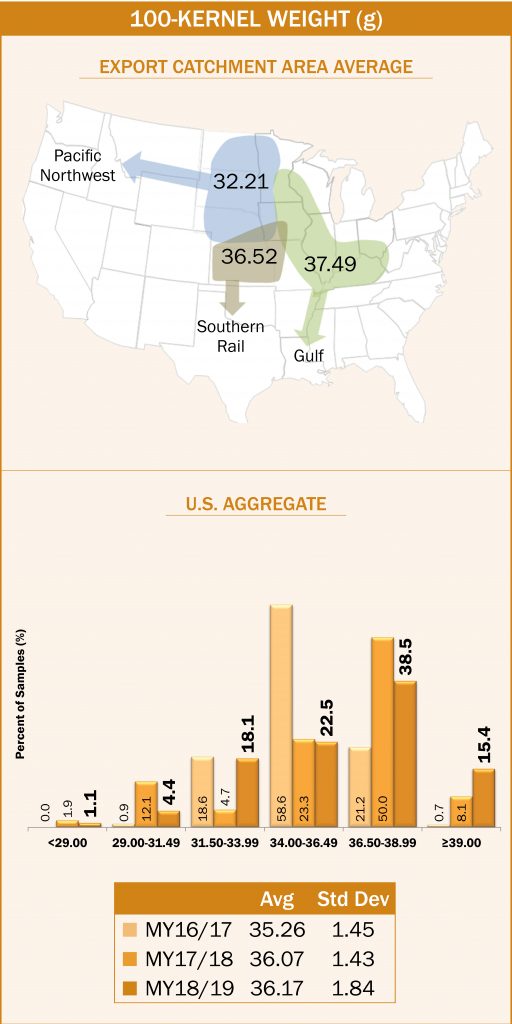

- Average U.S. Aggregate 100-kernel weight (36.17 g) was higher than 2017/2018 (36.07 g), 2016/2017 (35.26 g) and the 5YA (35.42 g).

- Average 100-kernel weight for export (36.17 g)

was higher than at harvest (35.07 g). From 2011/2012 through 2017/2018, average 100-kernel weights ranged from 0.00 to 2.05 g higher at export than at harvest. Since 100-kernel weight is based on 100 fully intact kernels, any breakage or reduction in whole kernels occurring in transit may have self-selected out small kernels with low 100-kernel weights that might have been more prone to breakage. - The export samples had a lower standard deviation (1.84 g) than the 2018 harvest samples (2.84 g). The 100-kernel weight standard deviation was also lower at export than at harvest for 2017/2018, 2016/2017 and the 5YA, indicating greater uniformity at export than at harvest.

- The average 100-kernel weight for the Gulf ECA (37.49 g) was higher than the Pacific Northwest (32.21 g) and the Southern Rail (36.52 g) ECAs.

- In 2018/2019, 53.9% of the samples had a 100-kernel weight of 36.5 g or higher, compared with 58.1% in 2017/2018 and 21.9% in 2016/2017. Thus, 2018/2019 and 2017/2018 had a higher percentage of large kernels than in 2016/2017.

- 100-kernel weight for contracts loaded as U.S. No. 2 or better (36.03 g) was lower than for contracts loaded as U.S. No. 3 or better (36.82 g).