100-Kernel Weight

100-kernel (100-k) weight (reported in grams) indicates larger kernel size as 100-k weights increase. Kernel size affects drying rates. As kernel size increases, the volume-to-surface area ratio becomes higher, and as the ratio gets higher, drying becomes slower. In addition, large uniform-sized kernels often enable higher flaking grit yields in dry milling. Kernel weights tend to be higher for specialty varieties of corn that have high amounts of horneous (hard) endosperm.

Results

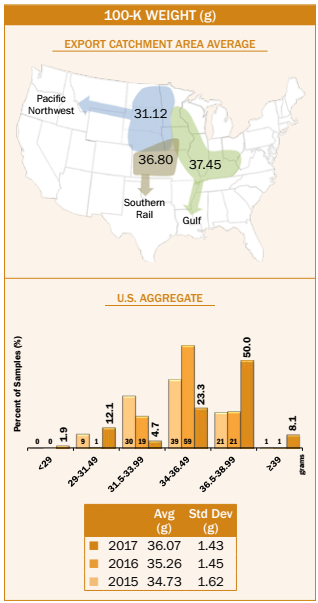

- Average U.S. Aggregate 100-k weight (36.07 g) was higher than 2016/2017 (35.26 g), 2015/2016 (34.73 g) and 5YA (35.37 g).

- Average 100-k weight for export (36.07 g) and harvest (36.07 g) were the same. However, in past years 2011/2012 through 2016/2017, average 100-k weights ranged from 0.06 to 2.05 g higher at export than at harvest. Since 100-k weight is based on 100 fully intact kernels, breakage or reduction in whole kernels occurring in transit may have self-selected out small kernels with low 100-k weights that might have been more prone to breakage.

- The export samples had a lower standard deviation (1.43 g) than the 2017 harvest samples (2.53 g). The 100-k weight standard deviation was also lower at export than at harvest for 2016/2017, 2015/2016 and 5YA, indicating greater uniformity at export than at harvest.

- The average 100-k weight for the Gulf ECA (37.45 g) was higher than the Pacific Northwest (31.12 g) and the Southern Rail (36.80 g) ECAs.

- In 2017/2018, 58.1% of the samples had 100-k weight of 36.5 g or higher, compared with 22% in both 2016/2017 and 2015/2016. Thus, a higher percentage of kernels were heavier than 36.5 g in 2017/2018 than in the previous two years.

- 100-k weight for contracts loaded as U.S. No. 2 o/b (36.31 g) was slightly higher than for contracts loaded as U.S. No. 3 o/b (36.13 g).