Whole Kernels

Though the name suggests some inverse relationship between whole kernels and broken corn and foreign material (BCFM), the whole kernels test conveys different information than the broken corn portion of the BCFM test. Broken corn is defined solely by the size of the material. Whole kernels, as the name implies, is the percent of fully intact kernels in the sample with no pericarp damage or kernel pieces chipped away. Some companies pay contracted premiums for corn delivered with low levels of “cracks and brokens,” meaning high percentages of whole kernels with fully intact pericarps.

The exterior integrity of the corn kernel is very important for two key reasons. First, it affects water absorption for alkaline cooking and steeping operations. Kernel nicks or pericarp cracks allow water to enter the kernel faster than fully intact or whole kernels. Too much water uptake during cooking can result in loss of solubles, non-uniform cooking, expensive shutdown time and/or products that do not meet specifications.

Second, intact whole kernels are less susceptible to storage molds and breakage during handling. While hard endosperm corn lends itself to preservation of more whole kernels than soft corn, the primary factor in delivering whole kernels is harvesting and handling. This begins with proper combine adjustment, followed by minimizing the severity of kernel impacts due to conveyors and the number of handlings required from the farm field to the end user. Each subsequent handling will generate additional breakage. Amounts of breakage increase exponentially as moisture decreases, as drop heights increase and/or a kernel’s velocity at impact increases.[1]

Results

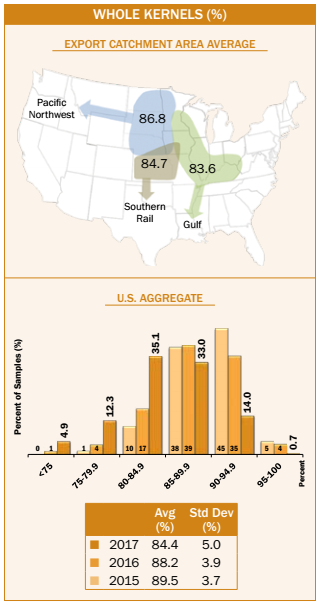

- Average U.S. Aggregate whole kernels (84.4%) was lower than 2016/2017 (88.2%), 2015/2016 (89.5%) and 5YA (88.9%).

- The average percentage of whole kernels at export in 2017/2018 was lower than at harvest (89.9%). Whole kernels for the export 5YA (88.9%) was also lower than for harvest 5YA (94.1%). Over the past three years and 5YA, the percentages of whole kernels have been 5.2 to 7.0 percentage points lower at export than at harvest. This reduction in whole kernels from harvest to export is likely caused by the additional handling required to reach export loading locations.

- The 2017/2018 export samples had a range of 64.0 to 97.6% whole kernels (with a standard deviation of 5.0%), while the 2017 harvest samples had a similar range (67.0 to 99.2%) and standard deviation (4.6%).

- The Pacific Northwest ECA (86.8%) had the highest average whole kernels compared with the Gulf (83.6%) and Southern Rail (84.7%) ECAs.

- The percentage of 2017/2018 export samples with whole kernels greater than or equal to 90% was 14.7%, compared with 39% in 2016/2017 and 50% in 2015/2016, indicating a much lower percentage of whole kernels in 2017/2018 than in the previous two years.

- Average whole kernels for contracts loaded as U.S. No. 2 o/b was 84.1%, compared with 84.2% found for contracts loaded as U.S. No. 3 o/b.

[1] Foster, G.H. and L.E. Holman. 1973. Grain Breakage Caused by Commercial Handling Methods. USDA. ARS Marketing Research Report Number 968.