U.S. Export Corn Flow

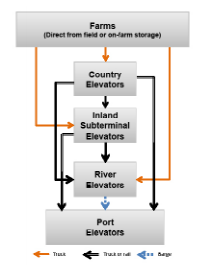

As corn is harvested, farmers transport grain to on-farm storage, end users, or commercial grain facilities. While many producers feed their corn production to their own livestock, the majority of the corn moves to other end users (feed mills or processors) or commercial grain handling facilities such as country elevators, inland subterminal or river elevators, and port elevators. Country elevators typically receive most of their grain directly from farmers. Subterminal elevators (either inland or river) collect grains in quantities suitable for loading on unit trains and barge tows for onward transport. These elevators receive more than half their corn from other elevators (usually country elevators) and are often located where the transport of bulk grain can be easily accommodated by unit trains or barges. Country, inland subterminal and river elevators can provide functions such as drying, cleaning, blending, storing and merchandising corn. The larger inland subterminal and river elevators supply most of the corn to port elevators intended for export markets. The following figure conveys the flow of U.S. corn destined for export markets.