Statistical Considerations

Only 35 of the targeted 50 samples for the Southern Rail ECA were collected due to low export volume during the sampling period. This reduced number of samples had implications on calculating the U.S. Aggregate statistics and on the ability to estimate the true average for total damage for the Southern Rail ECA. The U.S. Aggregate averages and standard deviations were weighted by ECA using the original sampling proportions.

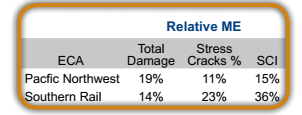

The Relative ME was calculated for each of the quality factors tested for this study at the U.S. Aggregate level and for each of the ECAs. The Relative ME was less than ± 10% for all the quality attributes at the U.S. Aggregate level and for the ECAs except for total damage, stress crack percent, and stress crack index for the Pacific Northwest and Southern Rail ECAs. The Relative ME for total damage, stress cracks percent and stress crack index were as follows:

While the lower level of precision for these quality factors in these two ECAs is less than desired, these levels of Relative ME do not invalidate the estimates. Footnotes in the summary tables for “Grade Factors and Moisture” and “Physical Factors” indicate the attributes for which the Relative ME exceeds ± 10%. With the 2011 samples as a basis, we will be able in future reports to use the variances from this year’s results to calculate sample sizes for these factors and adjust our sampling protocol to obtain a Relative ME of 10% or less.

Any references in the “Corn Quality Overview (2011/12 Export Cargo)” section to statistical differences are validated by two-tailed t-tests at the 95% confdence level that we calculated for results:

- Between factors in the Harvest Quality Report and Export Cargo Quality Report,

- Among factors in the Export Cargo Quality Report ECAs (Gulf, Pacific Northwest, Southern Rail), and

- Between factors in the Export Cargo Quality Report contract grades (U.S. No. 2 o/b, U.S. No. 3 o/b).

USDA’s Federal Grain Inspection Service (FGIS) provided official grading and aflatoxin results from its normal inspection and testing procedures for each sublot corn sample collected. The corn samples were sent directly from the FGIS field offices to the Illinois Crop Improvement Association Identity Preserved Grain Laboratory (IPGL) in Champaign, Illinois, for the chemical, physical factors, and DON testing. Upon arrival at IPGL, the samples were split into two subsamples using a Boerner divider. One subsample was delivered to the Champaign-Danville Grain Inspection (CDGI) agency for the DON testing. CDGI is the official grain inspection service provider for east-central Illinois as designated by FGIS. The other subsample was dried to approximately 15% moisture and analyzed at IPGL for the chemical composition and other physical factors following either industry norms or well-established procedures in practice for many years. IPGL has received accreditation under the ISO/IEC 17025:2005 International Standard.