D. Physical Factors

Physical factors are other quality attributes that are neither grade factors nor chemical composition. Physical factors include stress cracks, kernel weight, kernel volume, true density, percent whole kernels and percent horneous (hard) endosperm. Tests for these physical factors provide additional information about the processing characteristics of corn for various uses, as well as corn’s storability and potential for breakage in handling. These quality attributes are influenced by the physical composition of the corn kernel, which is in turn affected by genetics and growing and handling conditions. Corn kernels are made up of four parts: the germ or embryo, the tip cap, the pericarp or outer covering and the endosperm. The endosperm represents about 82% of the kernel and consists of soft (also referred to as floury or opaque) endosperm and of horneous (also called hard or vitreous) endosperm, as shown above. The endosperm contains primarily starch and protein; the germ contains oil and some protein, and the pericarp and tip cap are mostly fiber.

SUMMARY: PHYSICAL FACTORS

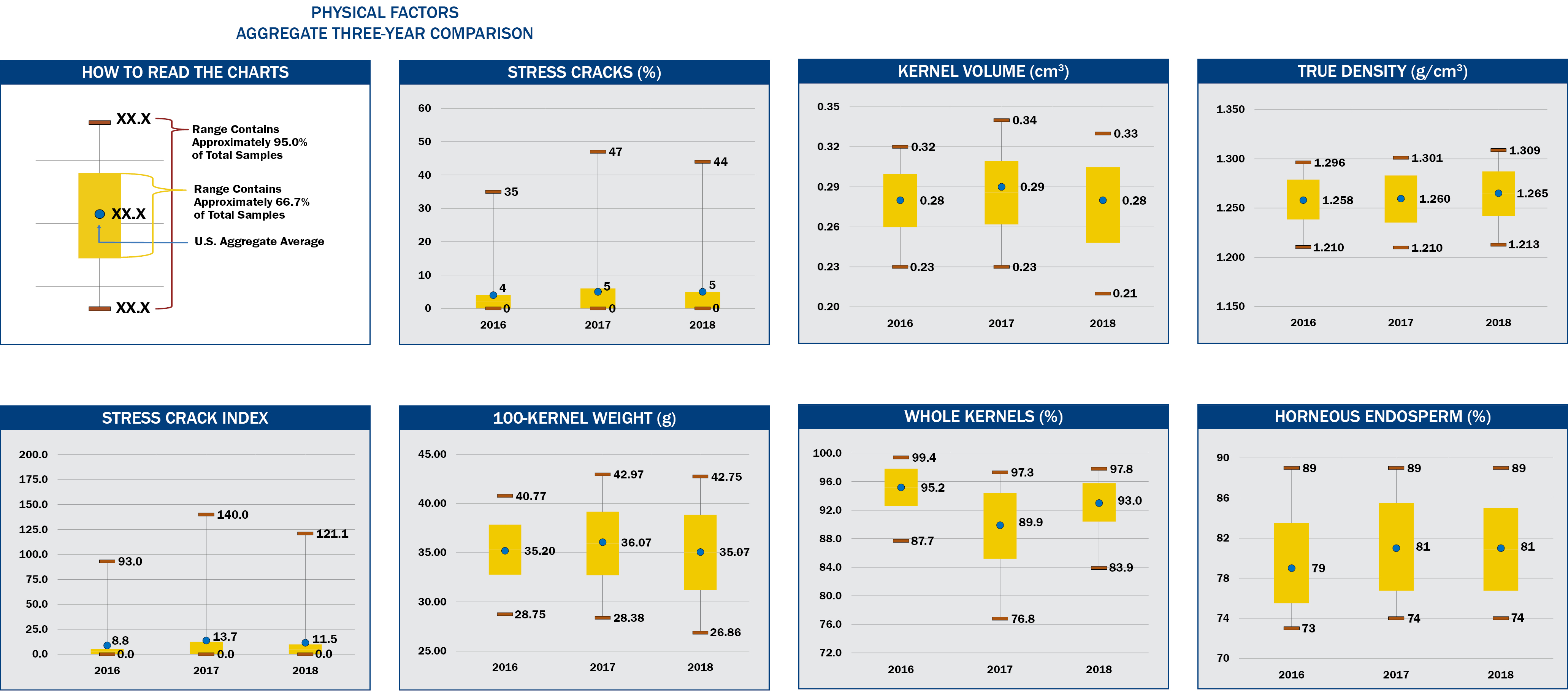

- Average U.S. Aggregate stress cracks (5%) and stress crack index (11.5) were close to 2017 and slightly lower than the 5YA, indicating corn’s susceptibility to breakage in 2018 may be similar to 2017 and slightly better than the 5YA.

- Among the ECAs, the Southern Rail ECA had the lowest stress crack averages and lowest stress crack index averages in 2018, 2017, 2016 and the 5YA.

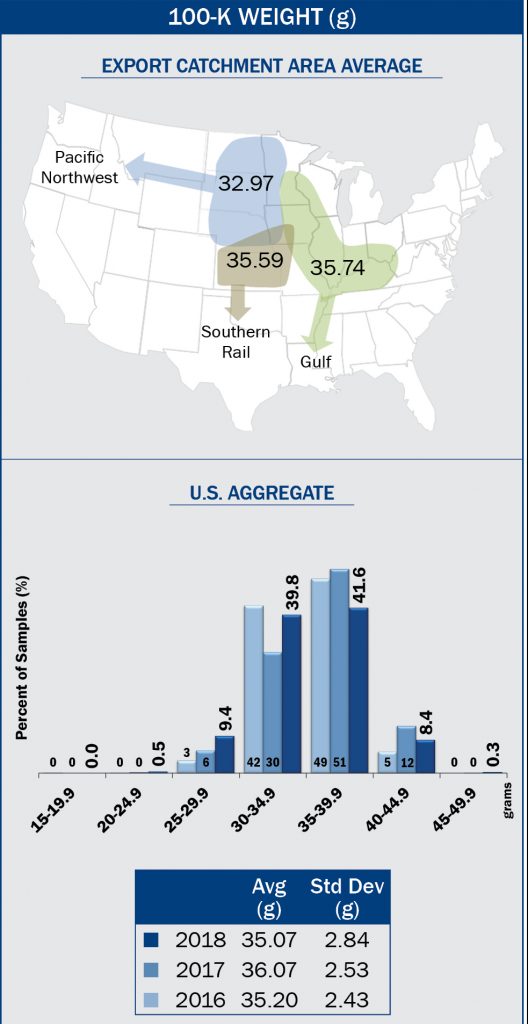

- Average U.S. Aggregate 100-k weight in 2018 (35.07 g) was lower than 2017, similar to 2016, but higher than the 5YA.

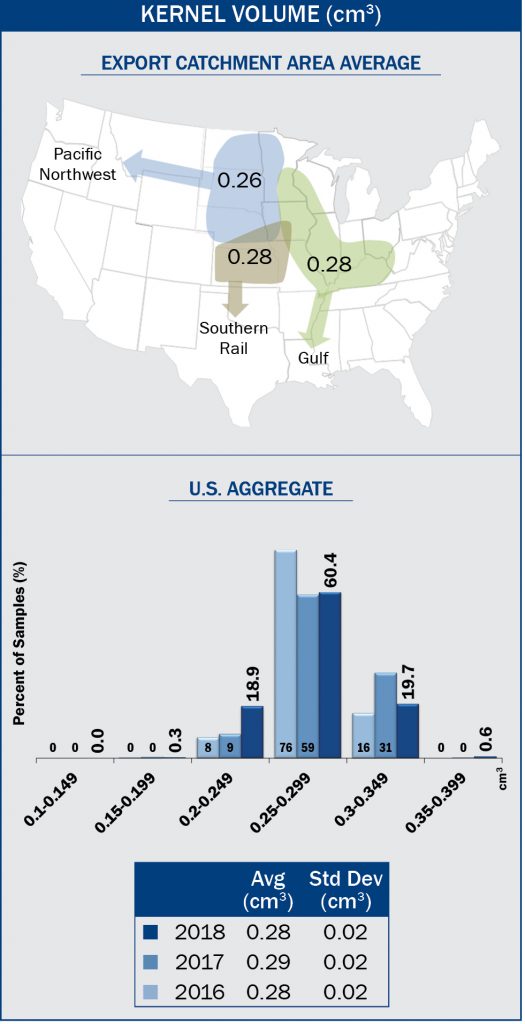

- Average U.S. Aggregate kernel volume in 2018 (0.28 cm3) was lower than 2017, but the same as 2016 and the 5YA. There was also a lower percentage of large kernels in 2018 than in 2017 but similar to 2016 and previous years.

- The Pacific Northwest ECA had the lowest 100-k weight average and the lowest kernel volume of the ECAs in 2018, 2017, 2016 and the 5YA.

- U.S. Aggregate kernel true density averaged 1.265 g/cm3 in 2018; was higher than in 2017, 2016 and the 5YA. True density kernel distributions above 1.275 g/cm3 in 2018 indicate harder corn than in 2017 and 2016. Of the ECAs, the Pacific Northwest had the lowest true density and lowest test weights in 2018, 2017, 2016 and the 5YA.

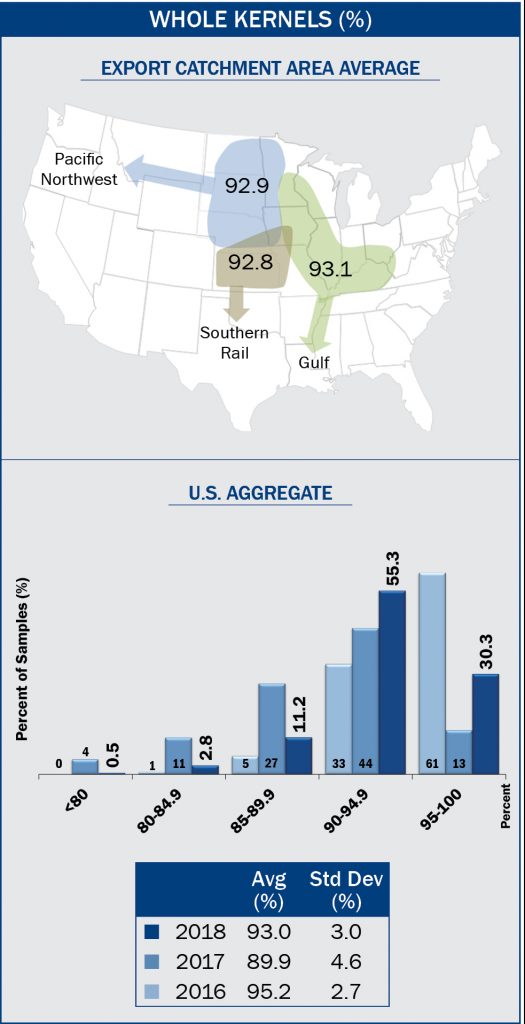

- U.S. Aggregate whole kernels averaged 93.0% in 2018; higher than in 2017, lower than 2016, but similar to the 5YA.

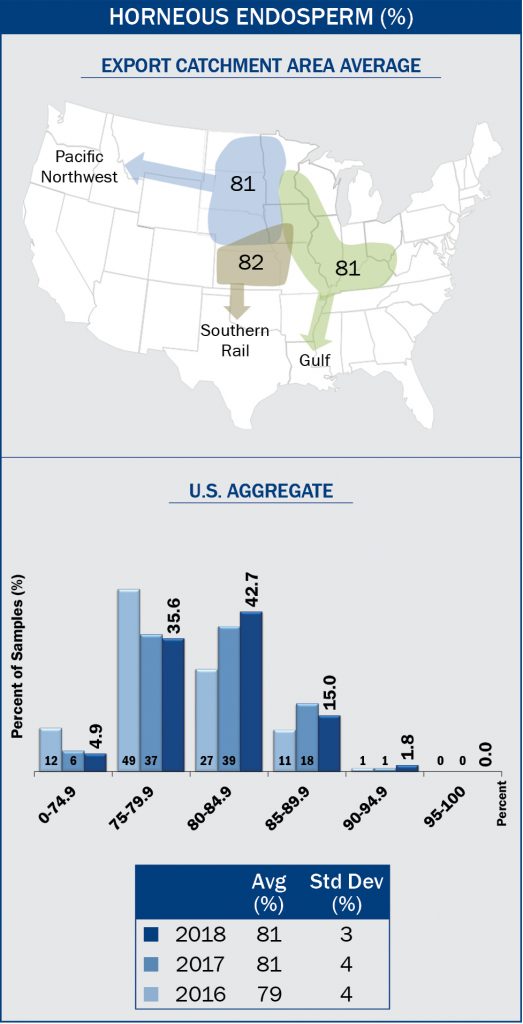

- Average U.S. Aggregate horneous (hard) endosperm (81%) was the same as 2017 and the 5YA, but higher than 2016 (79%). Average aggregate horneous endosperm in all ECAs was within one percentage point in 2018, 2017, 2016 and the 5YA. Average horneous endosperm tends to increase in years with higher true density.

1. Stress Cracks

Stress cracks are internal fissures in the horneous (hard) endosperm of a corn kernel. The pericarp (or outer covering) of a stress-cracked kernel is typically not damaged, so the kernel may appear unaffected at first glance, even if stress cracks are present.

Stress crack measurements include “stress cracks” (the percentage of kernels with at least one crack) and stress crack index, which is the weighted average of single, double and multiple stress cracks. Both measurements use the same sample of 100 intact kernels with no external damage. “Stress cracks” measures only the number of kernels with stress cracks; whereas, the stress crack index shows the severity of stress cracking. For example, if half of the kernels have only a single stress crack, “stress cracks” is 50% and the stress crack index is 50 (50 x 1). However, if half of the kernels have multiple stress cracks (more than two cracks), indicating a higher potential for handling breakage, “stress cracks” remains at 50%, but the stress crack index becomes 250 (50 x 5). Lower values for “stress cracks” and the stress crack index are always more desirable. In years with high levels of stress cracks, the stress crack index provides valuable information, because high stress crack index numbers (perhaps 300 to 500) indicate the sample had a very high percentage of multiple stress cracks. Multiple stress cracks are generally more detrimental to quality changes than single stress cracks.

The cause of stress cracks is pressure buildup due to moisture and temperature gradients within the kernel’s horneous endosperm. This can be likened to the internal cracks that appear when an ice cube is dropped into a lukewarm beverage. The internal stresses do not build up as much in the soft, floury endosperm as in the hard, horneous endosperm; therefore, corn with a higher percentage of horneous endosperm is more susceptible to stress cracking than softer grain. A kernel may vary in severity of stress cracking and can have one, two or multiple stress cracks. The most common cause of stress cracks is high-temperature drying that rapidly removes moisture. The impact of high levels of stress cracks on various uses includes:

- General: Increased susceptibility to breakage during handling. This may lead to processors needing to remove more broken corn during cleaning operations and a possible reduction in grade and/or value.

- Wet Milling: Lower starch yields due to the increased difficulty in separating starch and protein. Stress cracks may also alter steeping requirements.

- Dry Milling: The lower yield of large flaking grits (the prime product of many dry milling operations).

- Alkaline Cooking: Non-uniform water absorption leading to overcooking or undercooking, which affects the process balance.

Growing conditions will affect crop maturity, timeliness of harvest and the need for artificial drying, which will influence the degree of stress cracking found from region to region. For example, late maturity or late harvest caused by weather-related factors, such as rain-delayed planting or cool temperatures, may increase the need for artificial drying, thus potentially increasing the occurrence of stress cracks.

RESULTS

- U.S. Aggregate stress cracks in 2018 averaged 5%; same as 2017, higher than 2016 (4%), but lower than the 5YA (6%).

- U.S. Aggregate stress cracks standard deviation in 2018 (6%) was similar to 2017 (8%), 2016 (6%) and the 5YA (7%).

- Stress cracks ranged from 0% to 88% in 2018; similar to the ranges in 2017 (0% to 90%) and 2016 (0% to 84%).

- The percentage of samples with less than 10.0% stress cracks in 2018 (89.0%) was similar to 2017 (87%) but lower than 2016 (92%). Also, in 2018, 6.3% of the samples had stress cracks above 20.0%, which is intermediate to 2017 (8%) and 2016 (5%).

- Stress crack distributions indicate that 2018 corn should be similar in breakage susceptibility to 2017 but slightly higher than in 2016.

- Stress crack averages in 2018 for Gulf, Pacific Northwest and Southern Rail ECAs were 4%, 7% and 3%, respectively. Among all ECAs, the Southern Rail had the lowest stress cracks in 2018, 2017, 2016 and the 5YA.

- U.S. Aggregate stress crack index in 2018 averaged 11.5; lower than 2017 (13.7) and the 5YA (14.4), but higher than in 2016 (8.8).

- U.S. Aggregate stress crack index standard deviation in 2018 (16.8) was slightly lower than in 2017 (23.6) and the 5YA (22.9).

- Of the 2018 samples, 92.2% had a stress crack index of less than 40, which is similar to 2017 (90%) and 2016 (95%). Thus, the stress crack index distribution in 2018 was similar to those in 2017 and 2016.

- Stress crack index averages for the Gulf, Pacific Northwest and Southern Rail ECAs were 10.2, 18.0 and 6.6, respectively. The Southern Rail ECA had the lowest stress crack index in 2018, 2017, 2016 and the 5YA. The low stress crack index found for this ECA is likely related to more favorable field drying potential typically found in the states that constitute the Southern Rail ECA.

- The 2018 crop had a combined good-to-excellent condition rating that remained between 68% to 77% for most of the season. Silking percentages were ahead of previous years, enabling good maturation. Harvest started early but then further harvesting was delayed by rain. Average moistures (16.0%) were below 2017 and the 5YA. Warm September temperatures for much of the corn belt likely led to good drying conditions and the opportunity for reasonably low stress cracks. The 2016 year stands out for earliest planting and emergence, highest ratings for good-to-excellent crop condition and earliest harvest. That year had the lowest stress cracks (4%) and stress crack index (8.8) as well as relatively low moisture (16.1%). However, 2018 ranks close behind with stress cracks (5%), stress crack index (11.5) and lower moisture (16.0%).

2. 100-Kernel Weight

100-kernel (100-k) weight (reported in grams) indicates a larger kernel size as 100-k weight increases. Kernel size affects drying rates. As kernel size increases, the volume-to-surface-area ratio becomes higher, and as the ratio gets higher, drying becomes slower. In addition, large, uniform-sized kernels often enable higher flaking grit yields in dry milling. Kernel weights tend to be higher for specialty varieties of corn that have high amounts of horneous (hard) endosperm.

RESULTS

- U.S. Aggregate 100-k weight in 2018 averaged 35.07g; lower than in 2017 (36.07 g), similar to 2016 (35.20 g), but higher than the 5YA (34.61 g).

- Variability in the 2018 U.S. Aggregate 100-k weight (standard deviation of 2.84 g) was higher than 2017 (2.53 g) and 2016 (2.43 g), but similar to the 5YA (2.62 g).

- 100-k weight range in 2018 (23.86 g to 45.88 g) was similar to 2017 (23.06 g to 46.44 g) and 2016 (18.91 g to 44.17 g).

- The 100-k weights in 2018 were distributed with 50.3% of the samples having 100-k weight of 35.0 g or greater, compared to 63% in 2017 and 54% in 2016. This distribution indicates a slightly lower percentage of large kernels were found in 2018 compared to 2017, but the distribution was close to that in 2016.

- Average 100-k weight was lowest for the Pacific Northwest ECA (32.97 g), compared to the Gulf (35.74 g) and Southern Rail (35.59 g) ECAs. The Pacific Northwest ECA had the lowest 100-k weight in 2018, 2017, 2016 and the 5YA.

3. Kernel Volume

Kernel volume, measured in cubic centimeters (cm3), is often indicative of growing conditions. If conditions are dry, kernels may be smaller than average. If drought hits later in the season, kernels may have lower fill. Small or round kernels are more difficult to degerm. Additionally, small kernels may lead to increased cleanout losses for processors and higher yields of fiber.

RESULTS

- U.S. Aggregate kernel volume averaged 0.28 cm3 in 2018; lower than 2017 (0.29 cm3), but the same as in 2016 and the 5YA (both 0.28 cm3).

- Kernel volume variability was constant across the years. The standard deviation for U.S. Aggregate kernel volume was 0.02 cm3 for 2018, 2017, 2016 and the 5YA.

- Kernel volume range in 2018 (0.19 cm3 to 0.36 cm3) was similar to 2017 (0.18 cm3 to 0.36 cm3) and 2016 (0.16 cm3 to 0.34 cm3).

- The kernel volumes in 2018 were distributed with 20.3% of the samples having kernel volumes of 0.30 cm3 or greater, compared to 2017 (31%) and 2016 (16%). This distribution indicates there was a lower percentage of large kernels in 2018 compared to 2017, but the distribution was similar to 2016.

- Kernel volume for the Gulf, Pacific Northwest and Southern Rail ECAs averaged 0.28 cm3, 0.26 cm3 and 0.28 cm3, respectively. Among the ECAs, the Pacific Northwest ECA had the lowest average kernel volume in 2018, 2017, 2016 and the 5YA.

4. Kernel True Density

Kernel true density is calculated as the weight of a 100-k sample divided by the volume, or displacement, of those 100 kernels and is reported as grams per cubic centimeter (g/cm3). True density is a relative indicator of kernel hardness, which is useful for alkaline processors and dry millers. True density may be affected by the genetics of the corn hybrid and the growing environment. Corn with higher density is typically less susceptible to breakage in handling than lower density corn but is also more at risk for the development of stress cracks if high-temperature drying is employed. True densities above 1.30 g/cm3 indicate very hard corn, which is typically desirable for dry milling and alkaline processing. True densities near the 1.275 g/cm3 level and below tend to be softer, but process well for wet milling and feed use.

RESULTS

- Average U.S. Aggregate kernel true density in 2018 (1.265 g/cm3) was higher than in 2017 (1.260 g/cm3), 2016 and the 5YA (both 1.258 g/cm3). Over the past eight years, true densities have tended to be higher in years with higher protein.

- Variability, based on the standard deviation, in 2018 (0.018 g/cm3) was the same as 2017 and 2016 (both 0.018 g/cm3) and similar to the 5YA (0.019 g/cm3).

- True densities in 2018 ranged from 1.167 g/cm3 to 1.374 g/cm3 compared to 1.135 g/cm3 to 1.332 g/cm3 in 2017 and 1.162 g/cm3 to 1.320 g/cm3 in 2016.

- About 35.9% of the 2018 samples had true densities at or above 1.275 g/cm3 compared to 29% in 2017 and 23% in 2016. Since corn with values above 1.275 g/cm3 is often considered to represent hard corn and values below 1.275 g/cm3 is often considered to represent soft corn, this kernel distribution indicates slightly harder corn in 2018 than in 2017 and 2016.

- In 2018, kernel true densities for the Gulf, Pacific Northwest and Southern Rail ECAs averaged 1.266 g/cm3, 1.257 g/cm3 and 1.274 g/cm3, respectively. The Pacific Northwest ECA’s average true density and test weight were lower than the other ECAs’ values in 2018, 2017, 2016 and the 5YA.

- Test weight, also known as bulk density, is based on the amount of mass contained in a quart cup. While test weight is influenced by true density, as shown in the adjacent figure (resulting in a correlation coefficient of 0.71),

it is also affected by moisture content, pericarp damage (whole kernels), breakage and other factors. In 2018, test weight was 58.4 lb/bu, which was the same as 2017 and similar to 2016 (58.3 lb/bu).

5. Whole Kernels

Though the name suggests some inverse relationship between whole kernels and BCFM, the whole kernels test conveys different information than the broken corn portion of the BCFM test. Broken corn is defined solely by the size of the material. Whole kernels, as the name implies, is the percent of fully intact kernels in the sample with no pericarp damage or kernel pieces chipped away.

The exterior integrity of the corn kernel is very important for two key reasons. First, it affects water absorption for alkaline cooking and steeping operations. Kernel nicks or pericarp cracks allow water to enter the kernel faster than intact or whole kernels. Too much water uptake during cooking can result in loss of soluble, non-uniform cooking, expensive shutdown time and/or products that do not meet specifications. Some companies pay contracted premiums for corn delivered above a specified level of whole kernels.

Second, intact whole kernels are less susceptible to storage molds and breakage in handling. While hard endosperm lends itself to the preservation of more whole kernels than soft corn, the primary factor in delivering whole kernels is harvesting and handling. This begins with proper combine adjustment followed by the severity of kernel impacts due to conveyors and number of handlings required from the farm field to the end user. Each subsequent handling will generate additional breakage. Actual amounts of breakage increase exponentially as moisture decreases, drop heights increase and/or a kernel’s velocity at impact increases.3 In addition, harvesting at higher moisture contents (e.g., greater than 25%) will usually lead to soft pericarps and more pericarp damage to corn than when harvesting at lower moisture levels.

RESULTS

- U.S. Aggregate whole kernels averaged 93.0% in 2018; higher than in 2017 (89.9%), lower than in 2016 (95.2%), but similar to the 5YA (93.2%).

- The 2018 whole kernel standard deviation (3.0%) was lower than in 2017 (4.6%), but similar to 2016 (2.7%) and the 5YA (3.4%).

- Whole kernel range in 2018 (66.0% to 98.6%) was similar to 2017 (67.0% to 99.2%) and 2016 (80.6% to 100.0%).

- Of the 2018 samples, 85.6% had 90.0% or higher whole kernels, compared to 2017 (57%) and 2016 (94%). This distribution indicates 2018 had a higher percentage of whole kernels than the samples in 2017. The lower percentage of whole kernels in 2017 may in part be due to the exceptionally large kernel sizes found in 2017, which may have a weaker kernel structure than that of small kernels, leading to more cracking and chipping during combining and handling.

- Whole kernel averages for Gulf, Pacific Northwest and Southern Rail ECAs were 93.1%, 92.9% and 92.8%, respectively.

6. Horneous (Hard) Endosperm

The horneous (hard) endosperm test measures the percent of horneous or hard endosperm out of the total endosperm in a kernel, with a potential value from 70% to 100%. The greater the amount of horneous endosperm relative to soft endosperm, the harder the corn kernel is said to be. The degree of hardness is important depending on the type of processing. A hard kernel is needed to produce high yields of large flaking grits in dry milling. Hard to medium hardness is desired for alkaline cooking. Medium to soft hardness is used for wet milling and livestock feeding.

Hardness has been correlated to breakage susceptibility, feed utilization/efficiency and starch digestibility. As a test of overall hardness, there is no good or bad value for horneous endosperm; there is only a preference by different end users for particular ranges. Many dry millers and alkaline cookers would like greater than 85% horneous endosperm, while wet millers and feeders would typically like values between 70% and 85%. However, there are certainly exceptions in user preference.

RESULTS

- Average U.S. Aggregate horneous endosperm in 2018 (81%) was the same as 2017 and the 5YA (both 81%), but higher than 2016 (79%).

- U.S. Aggregate standard deviation for horneous endosperm was 3% in 2018; lower than 2017, 2016 and the 5YA (all 4%).

- The 2018 horneous endosperm range (72% to 92%) was similar to 2017 (71% to 92%) and 2016 (71% to 93%).

- Of the 2018 samples, 40.5% contained less than 80% horneous endosperm, which was a lower percentage than in 2017 (43%) and 2016 (61%). This indicates 2018 and 2017 had similar percentages of soft endosperm, but the percentage was much lower than 2016.

- Average horneous endosperm for the Gulf, Pacific Northwest and Southern Rail ECAs was 81%, 81% and 82%, respectively. Average horneous endosperm varied by no more than 0.1% across all ECAs during 2018, 2017, 2016 and the 5YA.

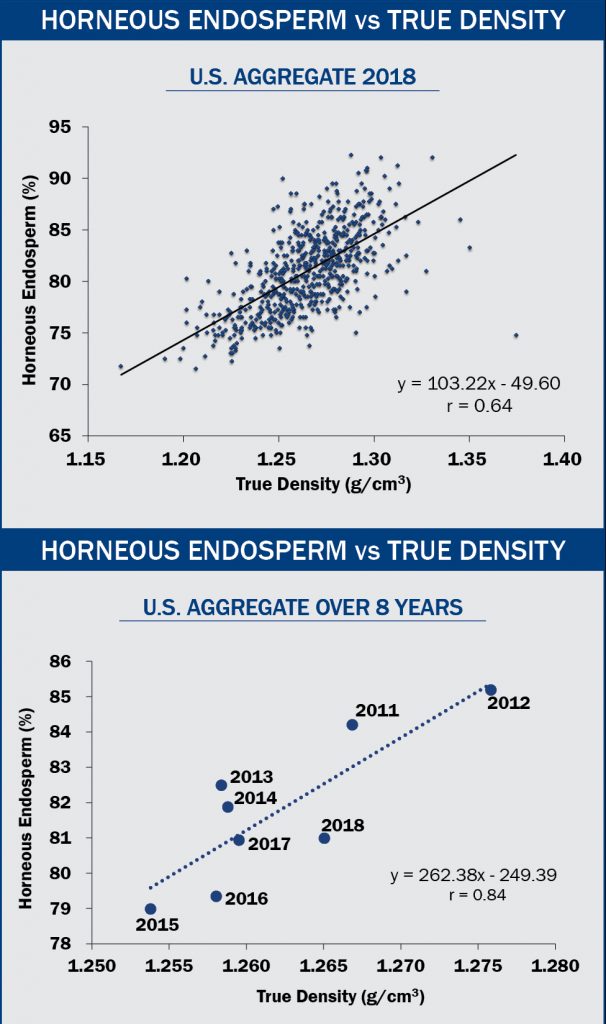

- The figure on the adjacent page shows a weak but positive relationship (a correlation coefficient of 0.64) between horneous endosperm and true density for the 2018 samples.

- The next figure shows the average U.S. Aggregate horneous endosperm and true density values over the past eight years. This illustrates that the average U.S. Aggregate horneous endosperm increases with true density (with a correlation coefficient of r = 0.84); thus, horneous endosperm tends to be higher in years when average true density is higher.