III. QUALITY TEST RESULTS

A. Grade Factors

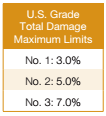

The USDA’s Federal Grain Inspection Service (FGIS) has established numerical grades, definitions and standards for grains. The attributes which determine the numerical grades for corn are test weight, broken corn and foreign material (BCFM), total damage and heat damage. The table for “U.S. Corn Grades and Grade Requirements” is provided on page 47 of this report.

SUMMARY: GRADE FACTORS AND MOISTURE

- Average quality of the corn at export was good and more uniform than at harvest and better than grade limits for U.S. No. 2 corn on all grade factors.

- The grade factor average values were generally better than the grade limits for contracts loaded as U.S. No. 2 o/b and for contracts loaded as U.S. No. 3 o/b.

- Average quality of the 2013/14 export samples was below that of the 2012/13 samples on all factors, but equal to or better than the 2011/12 samples on BCFM and total damage.

- Average test weight was lower than previous years (57.3 lb/bu (73.8 kg/hl)), but still above the limit for Grade U.S. No. 1.

- Approximately 65% of the export samples contained BCFM levels at or below the maximum allowed for U.S. No. 2 grade.

- Average total damage and heat damage were well below the limits for U.S. No. 1 grade.

- Moisture contents were lower at export than at harvest, thus improving storability and helping meet contract specifications at export.

- The distribution of sample moistures shows a higher percentage above 14.5% than in the previous two years.

1. Test Weight

Test weight (weight per volume) is a measure of bulk density and is often used as a general indicator of overall quality and as a gauge of endosperm hardness to alkaline cookers and dry millers. It reflects kernel hardness and kernel maturity. Test weight is initially impacted by genetic differences in the structure of the kernel. However, it is also affected by moisture content, method of drying, physical damage to the kernel (broken kernels and scuffed surfaces), foreign material in the sample, kernel size, stress during the growing season, and microbiological damage. High test weight at the port generally indicates high quality, high percent of horneous (or hard) endosperm and sound, clean corn.

RESULTS

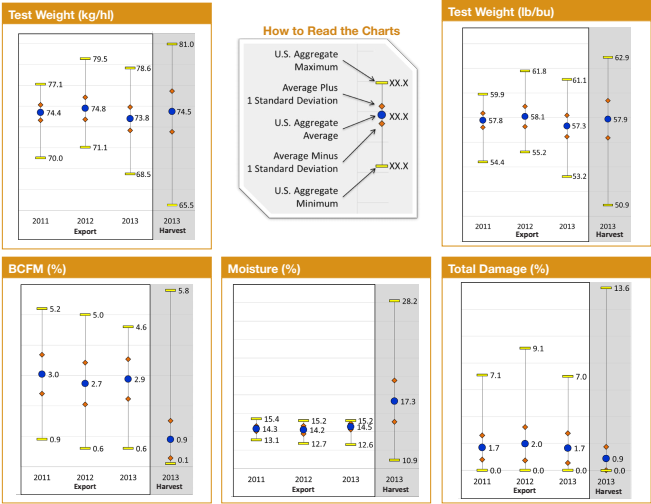

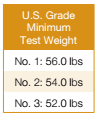

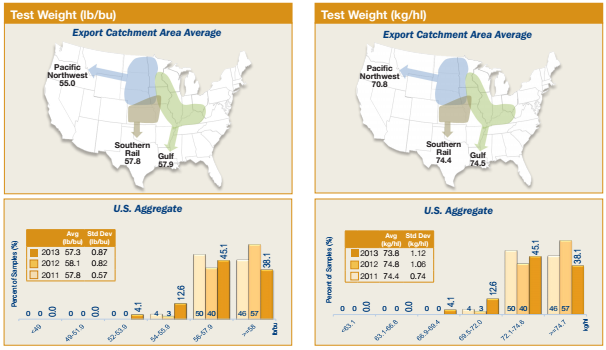

- U.S. Aggregate average test weight 57.3 lb/bu (73.8 kg/hl) was lower than the previous two years, but was above the grade limit for U.S. No. 1 corn (56.0 lb/bu).

- Over 83% of all samples’ test weights were at or above the minimum for U.S. No. 1 grade (56 lb/ bu) and 95.8% were above the limit for U.S. No. 2 grade (54 lb/bu). Only 4.1% of the samples fell below the U.S. No. 2 grade limit.

- Variation in the 2013/14 export samples was more than in previous years, as indicated by the higher standard deviation and wider range in values.

- The 2013/14 export samples’ variability was less than the harvest samples’ variability. As corn is commingled moving through the marketing channel, test weight may change somewhat, but it becomes more uniform with lower standard deviation and smaller range between maximum and minimum values.

- Test weight at export (57.3 lb/bu) was lower than test weight at harvest (57.9 lb/bu). This has been consistent for the previous two years.

- Test weight was significantly higher in samples from the Gulf ECA (57.9 lb/bu) and the Southern Rail ECA (57.8 lb/bu), with lower variability than samples from the Pacific Northwest ECA (55.0 lb/bu).

2. Broken Corn and Foreign Material (BCFM)

Broken corn and foreign material (BCFM) is an indicator of the amount of clean, sound corn available for feeding and processing. As corn moves from farm deliveries through the market channel, each impact on the grain during handling and transporting increases the amount of broken corn. As a result, the average BCFM in most shipments of corn will be higher at the export point than at the local elevator level.

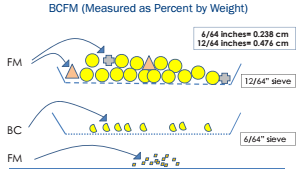

Broken corn (BC) is defined as corn and corn material small enough to pass through a 12/64th inch round-hole sieve, but too large to pass through a 6/64th inch round-hole sieve.

Foreign material (FM) is defined as any non-corn pieces too large to pass through a 12/64th inch sieve, as well as all fine material small enough to pass through a 6/64th inch sieve.

The diagram to the right illustrates the measurement of broken corn and foreign material for the U.S. corn grades.

RESULTS

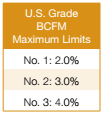

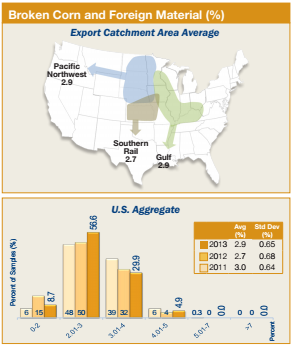

- Average BCFM in U.S. Aggregate export samples (2.9%) was below the maximum for U.S. No. 2 grade. It was significantly higher than in the 2012/13 samples (2.7%) but lower than in the 2011/12 samples (3.0%).

- BCFM among export samples was distributed with 65.3% of the samples at or below the grade limit for U.S. No. 2 (3%) and 95.2% at or below the grade limit for U.S. No. 3 (4%).

- The variability of the 2013/14 export samples (with a standard deviation of 0.65%) was approximately the same as that in 2012/13 (0.68%) and 2011/12 (0.64%).

- Average BCFM in contracts loaded as U.S. No. 2 o/b was 2.8% compared to the average BCFM of 3.0% in contracts loaded as U.S. No. 3 o/b. Corn arriving at the export point is often commingled from many origins to meet the limits for the contracted grade. Cleaning and loading procedures at the export point are designed to bring each factor close to but within the limits of each factor limit. Thus, BCFM would be expected to be lower in No. 2 than in No. 3 corn.

- Average BCFM at export (2.9%) was higher than at harvest (0.9%) as a result of increased breakage and stress cracks created by drying and handling impacts.

- BCFM at export was significantly lower in the Southern Rail ECA (2.7%) than in either the Gulf or Pacific Northwest ECAs (2.9%).

3. Total Damage

Total damage is the percentage of kernels and pieces of kernels that are visually damaged in some way, including damage from heat, frost, insects, sprouting, disease, weather, ground, germ and mold. Most of these types of damage result in some sort of discoloration or change in kernel texture. Damage does not include broken pieces of grain that are otherwise normal in appearance. Mold damage and the associated potential for mycotoxins is the damage factor of greatest concern. Mold damage is usually associated with higher moisture content and high temperature during growing and/or storage conditions.

Corn with low levels of total damage is more likely to arrive at destination in good condition than corn with high levels of total damage. High levels of total damage have the potential of increasing moisture and microbiological activity during transport.

RESULTS

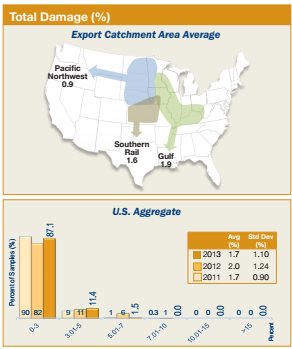

- U.S. Aggregate total damage (1.7%) was significantly lower than in 2012/13 (2.0%), well below the 3.0% limit for U.S. No. 1 corn.

- The average level for total damage increased significantly between the 2013 harvest (0.9%) and the 2013/14 export samples (1.7%).

- Of the export samples, 87.1% had 3.0% or less damaged kernels, meeting the requirement for No. 1. Only 1.5% of the samples were above the limit for U.S. No. 2.

- Variability in the 2013/14 export samples was lower than in 2012/13 as indicated by the standard deviations (1.10% compared with 1.24%) and the range (0.0% to 7.0% and 0.0% to 9.1%, respectively). However, the 2013/14 variability and levels were similar to those in 2011/12.

- Total damage in contracts being loaded as U.S. No. 3 (1.8%) was only slightly higher than for contracts being loaded as U.S. No. 2 o/b (1.7%).

- The Gulf ECA had the highest total damage (1.9%) compared with the Pacific Northwest (0.9%) and Southern Rail (1.6%) ECAs.

- The Gulf ECA also had the greatest increase in total damage between harvest (0.9%) and export (1.9%) of the three ECAs.

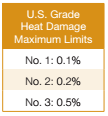

4. Heat Damage

Heat damage is a subset of total damage in corn grades and has separate allowances in the U.S. Grade standards. Heat damage can be caused by microbiological activity in warm, moist grain or by high heat applied during drying. Low levels of heat damage may indicate the corn has been stored at appropriate moisture and temperatures prior to delivery to the export point.

RESULTS

- Only four samples showed any heat damage, indicating good management of drying and storage of the corn through the market channel.