B. Moisture

Moisture content is reported on all official grade certificates, but does not determine which numerical grade will be assigned to the sample. Moisture content is usually specified in the contract by the buyer, independent of the grade. Moisture content is important because it affects the amount of dry matter being sold and purchased. In addition, the average moisture level and variability in a shipment of corn affect its quality arriving at destination. Corn is typically transported in railcars or in closed, nearly airtight holds during the ocean voyage, and few bulk carriers or railcars have the ability to aerate the grain mass during transit. This lack of aeration can create an ideal environment for pockets of high moisture to initiate microbiological activity. In addition, temperature variations in the grain mass can cause moisture migration, resulting in warm, moist air condensing on colder surfaces of grain, near sidewalls or on the underside of hatch covers, which can lead to development of spoilage or hot spots. Hot spots are small pockets of corn where the moisture content and temperature become abnormally higher than the average for the cargo. Thus, uniformity of moisture content among sublots and average moisture values below 14.5% are important for minimizing the risk of hot spots developing during transit.

RESULTS

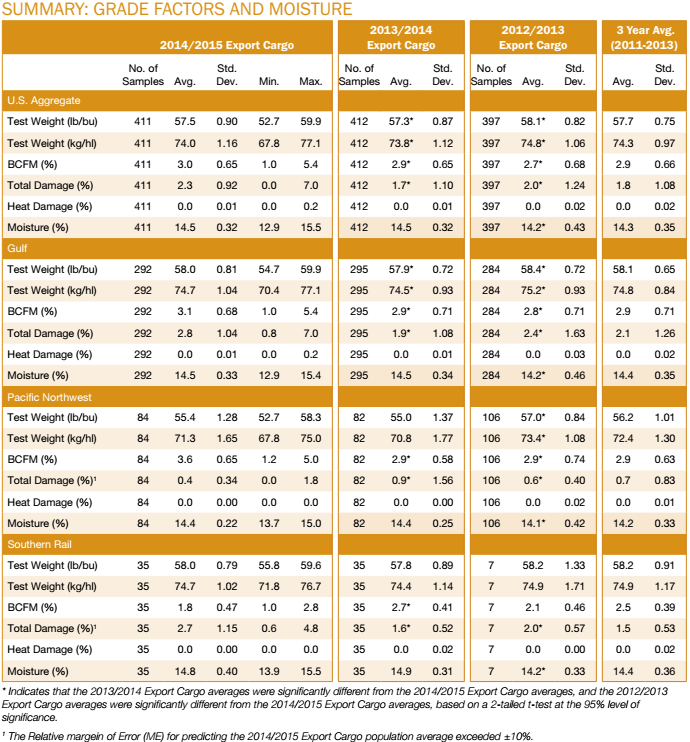

- Average U.S. Aggregate moisture content averaged 14.5%, the same as 2013/2014 but higher than 2012/2013 (14.2%) and 3YA (14.3%).

- Moisture content variability was similar among samples for 2014/2015 (standard deviation of 0.32%) and 2013/2014 (0.32%), but lower than 2012/2013 (0.43%) and 3YA (0.35%).

- Of the 2014/2015 export samples, 39.6% had moisture contents above 14.5%, compared to 48% in 2013/2014 and 19% in 2012/2013. The majority of the export samples (60.3%) had moisture contents of 14.5% or below.

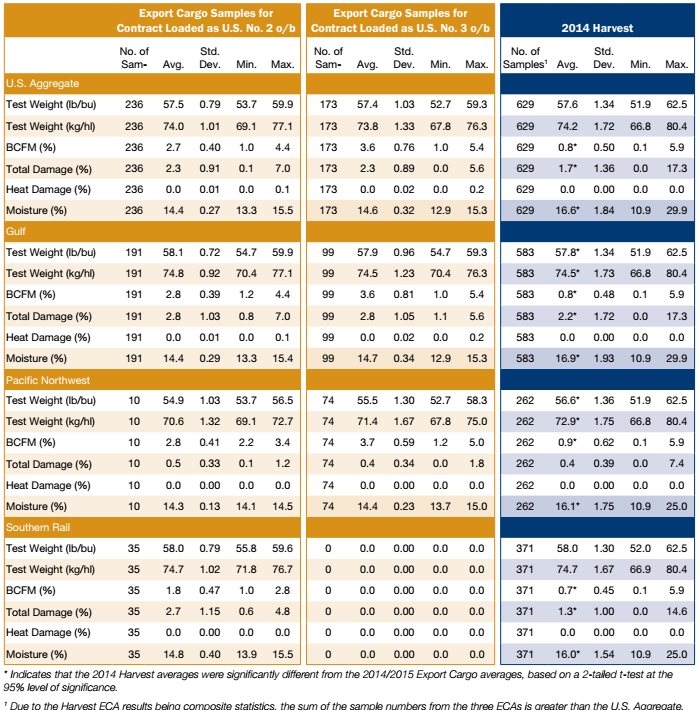

- Average moisture content decreased between harvest and export (from 16.6% to 14.5%) and uniformity among samples increased, as indicated by the lower standard deviations at export (0.32%) compared to harvest (1.84%) as a result of drying, conditioning, and commingling in the market channel following harvest.

- Average moisture in the 2014/2015 export samples from the Southern Rail ECA (14.8%) was higher than from the Gulf (14.5%) and the Pacific Northwest (14.4%) ECAs.

- Moisture content is not a grade-determining factor. However, it was slightly lower for contracts loaded as U.S. No. 2 o/b (14.4%) than for contracts loaded as U.S. No. 3 o/b (14.6%). Moisture standard deviation was also lower for U.S. No. 2 o/b (0.27%) than for U.S. No. 3 o/b (0.32%) contracts, indicating slightly more uniformity and less potential for pockets of higher moisture in the contracts loaded as U.S. No. 2 o/b than for contracts loaded as U.S. No. 3 o/b.