The U.S. Grains Council’s (USGC’s) Mexico office recently held a grain quality, grading and damage classification short course with Dr. Carlos Campabadal of the IGP Institute at Kansas State University to provide direct assistance to one of Mexico’s biggest cattle producers to address quality discrepancies in U.S. corn. However, the course quickly transitioned into a virtual workshop when Campabadal was able to offer a loading solution via Zoom to the feed-milling team experiencing problems.

Learn how the problem was addressed for this grain buying company in the following photo essay.

During the training, a manager from the feed mill in Mexicali shared out-of-the-ordinary discrepancies found during sampling before and after unloading to his bins. After hearing all the suggestions from Campabadal on consistent sampling, the feed mill manager followed protocols but was nevertheless still seeing varying consistencies of broken corn and foreign material (BCFM). During the live Zoom session, the feed mill manager shared a photo of his bin and a very steep unloader. He perceived this as a potential issue and requested Campabadal’s opinion.

The feed mill manager shared the photo above via screen share to demonstrate the issue. He followed correct sampling protocols but was still seeing varying consistencies of BCFM. The U.S. corn met specifications upon initial testing, but then failed after the supply reached their mill for steam rolling.

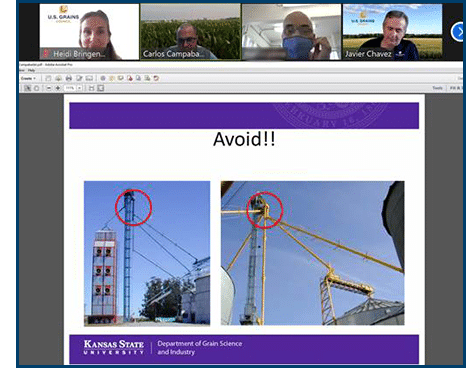

After a virtual analysis, Campabadal identified that the BCFM issue was compounded by the increased velocity at unloading due to the tall and steep unloading at the bin. He remembered a past presentation on the subject and quickly pulled it up to help explain the situation visually.

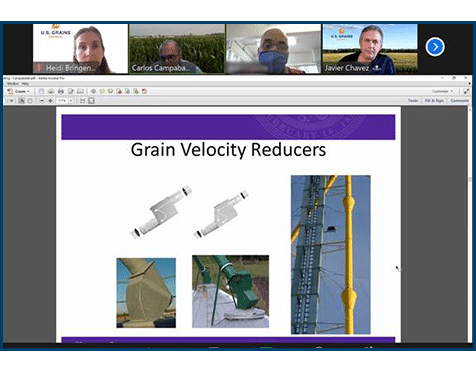

Campabadal offered the practical suggestion of using a velocity reducer to slow down the grain before it compounds the dust and creates BCFM as it reaches the bin.

Screen sharing via Zoom enabled the Council to quickly offer Campabadal’s technical support to the important corn buyer.

Since the session ended, the Council’s Mexico office heard from the feed mill managers that they were very pleased with their sampling results, mentioning that in addition to solving the grain velocity error, they also learned they were analyzing the rail hooper cars incorrectly. The guidance they received helped improve the results they are now getting.

“When the Council provides customers with tangible solutions for practical issues, it provides so much value beyond their bottom line,” said Heidi Bringenberg, USGC assistant director in Mexico.

“It also brings confidence in choosing U.S. grain origin for the long term. We have built trust and true partnership with this major end user. They can count on USGC to bring them the best grain and market professionals in the field and truly listen and offer personalized solutions. We look forward to resuming in-person programming, but this is a virtual example of success only possible by bringing 50 people together from around Mexico, Kansas and D.C. via Zoom technology.”

Read more information about the Council’s trade servicing in Mexico.

About The U.S. Grains Council

The U.S. Grains Council develops export markets for U.S. barley, corn, sorghum and related products including distiller’s dried grains with solubles (DDGS) and ethanol. With full-time presence in 28 locations, the Council operates programs in more than 50 countries and the European Union. The Council believes exports are vital to global economic development and to U.S. agriculture’s profitability. Detailed information about the Council and its programs is online at www.grains.org.